WWTP

with membrane

For more than 10 years we have been engaged in the development, production and installation of membrane wastewater treatment plants for family houses, boarding houses, hotels, municipalities and industry. We are specialists in membrane technology. The treated wastewater is suitable for recycling - watering plants, flushing toilets, as process water in a treatment plant or for reuse in industry. Would you like to sell this high quality products in your country? Become a member of our qualified team of business and service partner abroad.

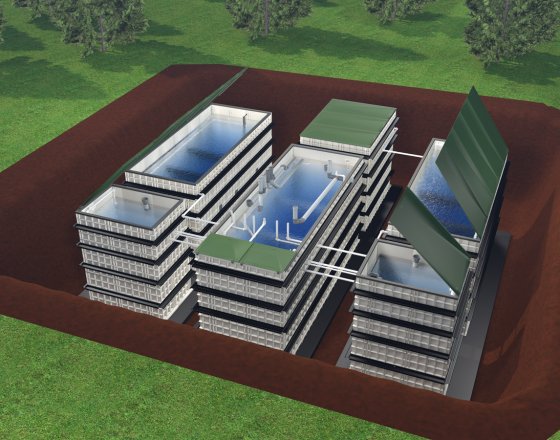

Membrane wastewater treatment plants

A membrane bioreactor (MBR) WWTP combines conventional biological wastewater treatment with membrane technologies. Separation of activated sludge in conventional wastewater treatment plants takes place in settling tanks. This method of separation therefore has its limits in the quality of purified water and in a higher demand on the composition of activated sludge. Membrane separation consists of suppression or microfiltration, where the mixture of purified water and sludge is filtered through vacuum through membranes and the resulting effluent (permeate) is free of almost all undissolved substances and microbial contamination, so the permeate is hygienically secured.

Advantages of membrane treatment plants:

- High quality purified water (permeate) suitable for recycling

- Thanks to the higher volume load of activation, the capacity of the existing treatment plant can be increased to 2-3 times the original capacity

- MBR can handle materially and hydraulically unstable inflow to the treatment plant

Overview of membrane wastewater treatment plants by capacity or wastewater producer

Domestic membrane wastewater treatment plants

The BC 6-30 MBR WWTP consists of two cylindrical tanks in which the first serves as a primary sedimentation and sludge storage while the second tank is activated with an inserted membrane module or modules. The treatment plants can be supplemented with phosphorus precipitation. The treatment plants have an international CE certificate.

Designed for: family houses or smaller guesthouses

The set contains:

- a plastic tank of WWTP

- technological installation including membrane module

- diaphragm blower, permeate pump

- control unit

- cover of WWTP

- initial training

Container membrane wastewater treatment plants

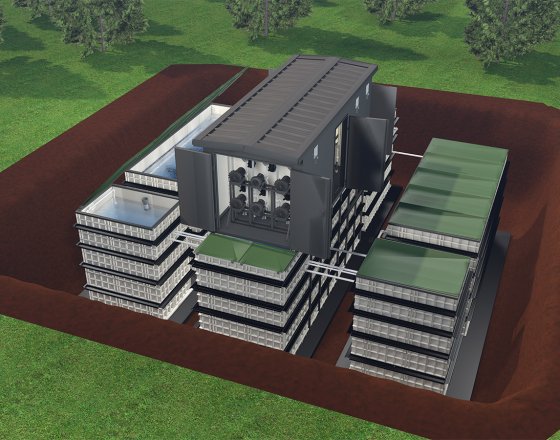

The BC 50-1100 MBR WWTP type series is placed in rectangular containers. The membrane chamber with inserted modules is always separate. According to the specific project, it is possible to choose the type of mechanical pre-cleaning, one or two-line arrangement incl. sludge tanks, phosphorus precipitation or automatic cleaning of membranes with chemicals. Treatment plants up to 50 EO have international CE certification.

Designed for: guesthouses, hotels, smaller businesses and municipalities

Mobile membrane wastewater treatment plants

The compact solution of mobile membrane WWTP is placed in an insulated steel container. The container is divided into individual parts: mechanical pre-cleaning, activation, membrane chamber and engine room.

Designed for: temporary and permanent wastewater treatment

Advantages of ENVI-PUR WWTPs

-

10+

More than 10 years of experience with membrane technologies

-

50

Number of installed membrane treatment plants

-

12

We use a quality membranes that have a durability of 12 years

-

0,04

0.04 microns is the pore size of the membrane polymer

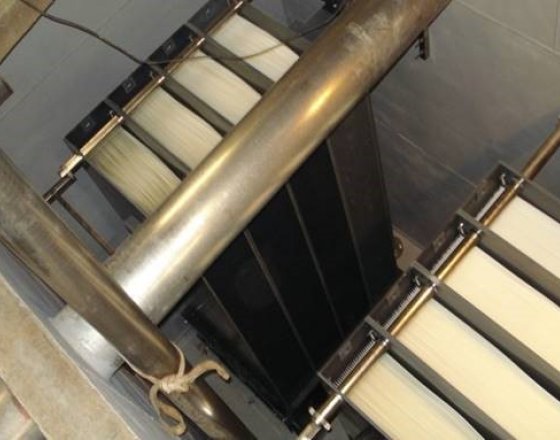

Membrane EP-UF

ENVI-PUR is a high quality membrane

- Long durability - up to 12 years

- Possibility of backwashing (incl. Dosing of chemicals) »thorough cleaning of the membrane» delaying to complete elimination of the need for regeneration »prolonging the life of membranes

- Self-healing ability in case of mechanical damage

- Unique frameless construction, which prevents settling of the sludge at the corners of the module

- Low pressure losses and high areal density

- Easy operation

Membrane cleaning

The customer's initial concerns about glazing and clogging of the membranes can be dispelled thanks to our numerous references, where one and the same membrane works without signs of significant wear, and tear, they filter for years. Depending on the size of the treatment plant, the membranes are cleaned using 4 steps:

- Air cleaning

- Backwash

- Backwash with chemicals

- Chemical regeneration

What about the energy performance of membrane WWTP?

We have used our many years of experience with membrane processes in optimizing the control system so that the lowest possible electricity consumption is achieved for all types and sizes of membrane treatment plants.

What about the difficulty of operating a membrane treatment plant?

In general, compared to a conventional treatment plant, the operation of a membrane treatment plant is less demanding. The control system for all sizes of treatment plants is responsible for the full automation of the entire technology. In larger treatment plants, the operator does not have to worry about the cleanliness of the settling tank, which is closely related to the quality of the outflow. Concerningthe manual activities, the operator is mainly responsible for the removal of scrapers and the control of any notifications from the control system.

Customer support

We are aware that each customer must be familiar with the membrane technology, therefore, it is for us a thorough operator training and subsequent technological support. We are able to provide service supervision of the treatment plant via remote access or on-site inspection.

We develop, educate and work with the best experts in our field

We cooperate with the universities of the VŠCHT Prague, VUT Brno, TU Liberec and the TAČR agency. We apply the acquired knowledge and skills in practice. We present ourselves at trade fairs and conferences.

We regularly organize our own professional conference.

Installation of two-lines WWTPs with the membrane for 400 EP

We will be happy to help you

If you have any questions, our experts will help you immediately.