Lamellar separation

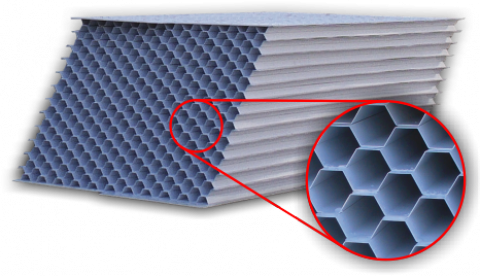

Lamellar packs

The lamellar´s packs increase the sedimentation surfaces, while reducing space and costs.

The lamellar´s separation block is made of molded plastic plates, placed and interconnected at an angle of 60 °. This creates a system of oblique parallel tubes of hexagonal cross-sections in the lamella block. The lamella blocks are repeatedly inserted into the supporting frame with the sampling trough - so-called packs. The packs with 2, 4, 6 and 8 blocks are mass-produced. The lamella block is a self-supporting block with two sloping walls.

Advantages:

- Efficiency

- Mechanical resistance

- Easy maintenance

- Resistance to chemical and biological elements

Parameters of the lamellar block

- Width 995 mm

- Length 720 mm

- Height 1310 mm

- Weight 40 kg

Projection area 17.4 m² / m²

EP-K series of lamella cassettes

|

Type |

Flow |

Weight |

Dimension(L×W×H) |

|

EP-K2 |

25 |

220 |

2 467 × 1 100 × 2 100 |

|

EP-K4 |

50 |

500 |

3 953 × 1 100 × 2 100 |

|

EP-K6 |

75 |

780 |

5 439 × 1 100 × 2 100 |

|

EP-K8 |

100 |

1 080 |

6 925 × 1 100 × 2 100 |

Clarifiers

ENVI-PUR clarifiers are a universal device for continuous separation of suspended solids from a liquid medium. Their applications are very extensive and include:

Drinking and technological water

- surface water clarification

- surface water softening

- groundwater softening

- separation of iron and copper from groundwater

Industrial waste water

- wastewater treatment by clarification and precipitation processes

Municipal wastewater

- phosphate removal by precipitation processes

·

The machine-technological design of the ENVI-PUR clarifier is an expression of the qualitative improvement of the determining technological steps taking place during the clarification of water, with the following result:

- progressive reduction of dwell times in the system

- high quality clarified water

- stable quality of clarified water with changes in the qualitative or quantitative load of the clarifier

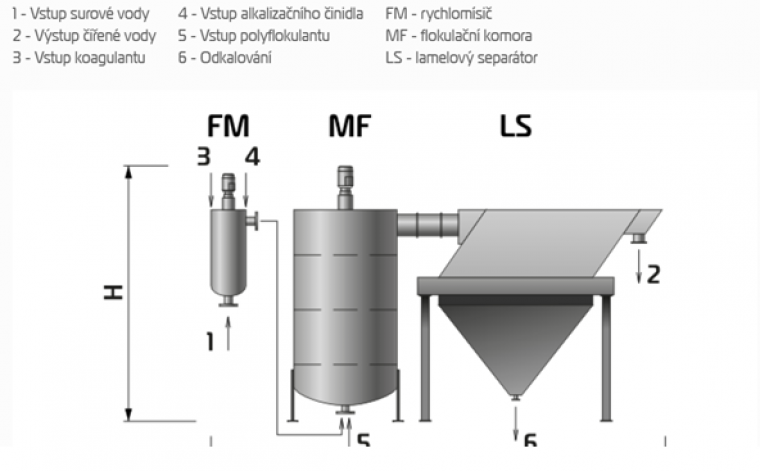

The success of a clarifying reactor is based on optimizing the function of the three basic technological modules of the plant, i.e. the high-speed mixer, the flocculation chamber and the lamellar separator. The fast mixer undergoes perfect homogenization of the raw water and metered chemicals, in the flocculation stage dense flakes are formed, which are reliably separated from the liquid in the space of the lamellar separator.

Technological scheme of the clarifier

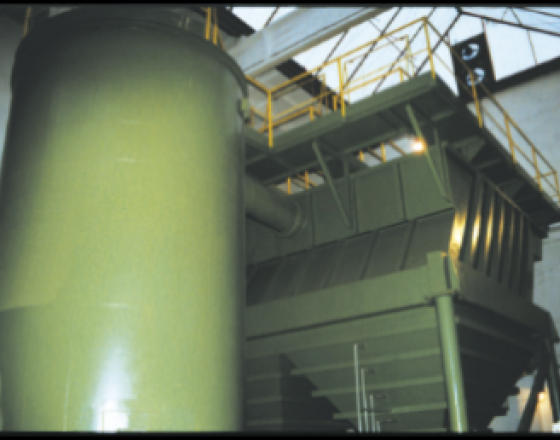

Lamellar separation on a turnkey basis

ENVI-PUR supplies all the technology for lamellar separation. We will design, plan and supply sedimentation tanks or complete clarifier technology, including the installation of a lamella installation. We are able to produce "tailor-made" above-ground steel clarifiers and of course the delivery of an automated system for controlling technological processes according to the customer requirements.

We are developing ...

We cooperate with the universities of the Institute of Chemical Technology in Prague (ČVUT), VUT Brno, TU Liberec and the TAČR agency. We apply the acquired knowledge and skills in practice. We present ourselves at trade fairs and conferences.

We regularly organize our own professional conference.

Technical specification of ENVI-PUR clarifiers

|

Type designation |

Equipment performance |

Equipment weight |

Dimension |

|

EP-C 5 |

5 |

500 |

2,75 × 1,50 × 2,20 |

|

EP-C 25 |

25 |

2 821 |

5,00 × 2,30 × 4,20 |

|

EP-C 50 |

50 |

4 892 |

5,40 × 3,61 × 4,20 |

|

EP-C 100 |

100 |

9 815 |

8,40 × 3,50 × 5,30 |

|

EP-C 200 |

200 |

16 837 |

10,60 × 4,90 × 6,40 |

|

EP-C 300 |

300 |

19 134 |

12,60 × 4,90 × 6,40 |

Rethinking water for more than 25 years

ENVI-PUR, s.r.o. is your experienced partner who understands water management.

Number 1 on the market

We treat drinking water for more than 4,500,000 inhabitants and treat waste water from over 1,000,000 EP.

More than 25 years of experiences

We have been supplying high quality products and services for a quarter of a century.

Implementations

We have thousands of successful implementations and hundreds of thousands of satisfied customers.

Turnover

Sales of our products and services in 2022.

Worldwide representatives

We operate in many abroad countries. Currently we have sales representatives in more than 10 countries and new challenges are still awaiting us.

We will be happy to help you

If you have any questions, our experts will help you immediately.