Pilot plant tests will assure you that the right wastewater treatment or water treatment technology has been chosen.

When designing a technological solution for wastewater treatment or water treatment, we attach importance to high-quality pre-project preparation.

Especially for industrial wastewater treatment, water recycling, or large municipal wastewater treatment projects, it is very appropriate to test the proposed solution in pilot plant tests.

Pilot tests will not only verify the accuracy of the design but also identify possible pitfalls of the project and help optimize the entire technological line before final construction.

Thanks to the pilot plant tests, it is possible to eliminate financial losses that might occur with an inconvenient design.

Overview of the pilot plant units

ENVI-PUR currently has several pilot plant units at its disposal. There are many varieties of how they can be combined or supplemented depending on the water’s character:

- Ceramic membrane filtration AMAYA

- Variable membrane unit

- MiFlo microbubble flotation

- Filtration unit for various fillings, e.g. GAC (Granulated activated carbon) for removing micropollutants

- Electrocoagulation unit

Description of the particular pilot plant units

Ceramic membrane filtration AMAYA

Description of the unit

The mobile ceramic membrane filtration unit AMAYA has a wide range of applications in both types of water - drinking and wastewater. The system works on the principle of direct filtration, so-called dead-end filtration. It is a one-stage water treatment with upstream coagulation.

The main benefit of this technology is its high efficiency in removing organic substances, color, turbidity, microorganisms, and viruses. This compact and robust technology stands out in long service life and low consumption of washing water.

Use

The model of ceramic membrane filtration is suitable to be used in pre-project preparation to verify the effectiveness of drinking water treatment. The model can also be used for emergency drinking water supply in crisis situations as part of IRS, or it can provide drinking water supply for sports and cultural events.

The unit can be used separately or in combination with a membrane wastewater treatment plant, it will find application in the verification of the wastewater recycling proposal.

Variable membrane unit

Description of the unit

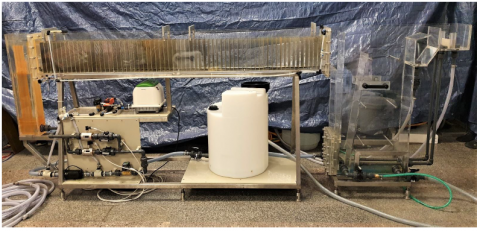

The variability of the unit lies in the possibility of choosing the type of membrane modules (ceramic or polymer), it is also possible to choose a pressure or vacuum system. An optional option is also the inclusion of an activation tank and the addition of the unit to the complete technological line of the membrane WWTP.

For physico-chemical pre-treatment of wastewater, flocculation chambers in combination with a lamellar separator or a tubular flocculator in combination with a lamellar separator or a tubular flocculator can be selected and then the suspension can be separated on the membrane.

Use

Designed for industrial wastewater, especially hardly biodegradable. The variable membrane unit can also be used on municipal wastewater. Pilot plant testing with a variable unit took place at two locations for the textile and engineering industries.

MOBILE ceramic membrane filtration unit AMAYA

Description of the unit

The mobile AMAYA ceramic membrane filtration unit is suitable for the treatment of water into drinking water. Water can be treated from underground sources or from surface sources such as rivers, ponds, streams, lakes and reservoirs.

The system works on the principle of direct filtration, so-called dead end filtration. It is a one-stage water treatment with upstream coagulation. The main benefit of this technology is high efficiency in removing organic substances, color, turbidity, microorganisms and viruses. This compact and robust technology excels in its long service life and low washing water consumption.

Use

This type of mobile ceramic membrane filtration can be used as an emergency source of drinking water, for example, during fires, floods, tornadoes, military operations or other crisis situations, where it can be part of the equipment of the Integrated Rescue System.

Commercially, mobile membrane filtration can be used as an additional source of drinking water wherever the consumption is occasionally significantly higher than the usual average, or wherever the source of drinking water is not available and drinking water has to be imported - sports events, cultural events, camps, children's camps, etc. We regularly rent our Amaya every summer to a boating camp in Vyšší Brod, where there is not enough drinking water to serve a high number of tourists in summer. Thanks to Amaye, the water from the river is treated into drinking water within a few seconds.

The model can be used in pre-project preparation to verify the effectiveness of drinking water treatment.

Microbubble flotation MiFlo

Description of the unit

Flotation is a separation process based on bringing pollution by microbubbles of air to the surface, used primarily for industrial wastewater treatment. MiFlo microbubble flotation uses rotating MicroGas ceramic membrane discs to create microbubbles™.

It is a compact technology with a small footprint that saves up to 90% electricity compared to DAF flotation. The advantage is also simple installation and maintenance, as well as a quick start-up of the technology after its shutdown.

Use

MiFlo will find employment in the food, textile and petrochemical industries. Further in the purification of waters from fish farming and agriculture.

Pilot plant filter unit for various fillings

Description of the unit

Filter unit is divided into three parts. A different filling can be tested in each part. Treated wastewater flows onto the filters, preferably from a membrane WWTP. The filters can be operated both in series and in parallel.

Use

For example, the unit was used to test the efficiency of removing micropollutants from wastewater by filtration through granular activated carbon. The aim is to remove pharmaceuticals and personal care products from the treated wastewater. By selecting the type of granular activated carbon, it is possible to compare the efficacy of individual types.

Pilot plant electrocoagulation unit

Description of the unit

The unit is a flow-through integrated device using a combination of hydrodynamic processes and electrocoagulation methods. The unit consists of an electrolyzer in which electrodes are inserted, from which, as current passes, ferric ions are released. This is followed by the aggregator, where the formation of flakes occurs. Another part of the unit is separation, which is either a lamellar separator or a flotation chamber.

Use

The unit can be used for wastewater, algae, wherever coagulation is needed. The unit was practically used for the separation of algae from the culture medium. In practice, its great advantage has been verified - low energy intensity of separation.

We will be happy to help you

If you have any questions, our experts will help you immediately.